Cnc Programming

G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants.

CNC MILLING GCODE MCODE SOLO CAD DESIGNER

Higher productivity thanks to upgrading to a new level of CNC motion control board. CNC Motion boards for smooth and efficient work - automation has never been easier.

CNC Programming Courses Cnc lathe, Cnc programming, Code programming

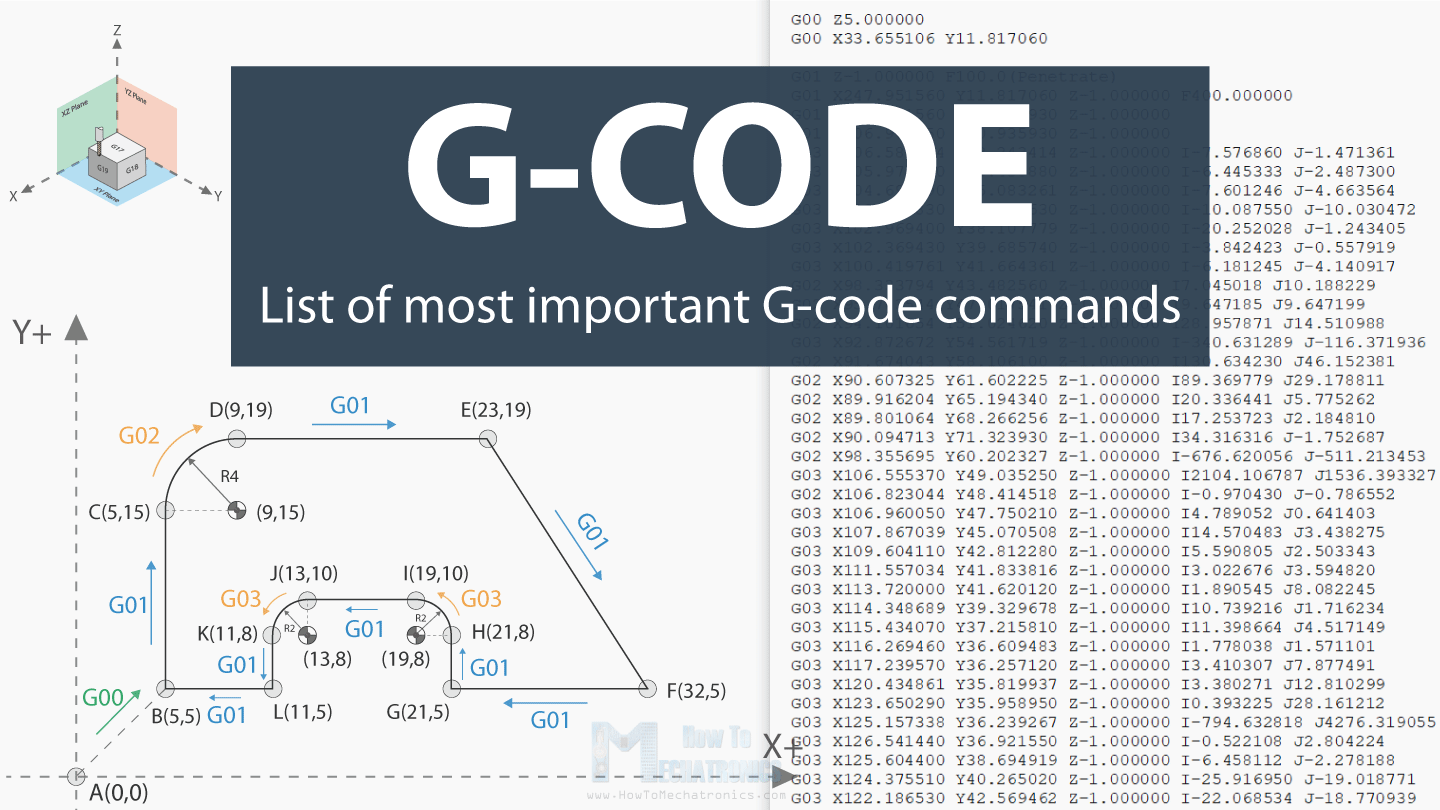

An example of a G-code section. There are different types of codes: 1/ Codes that start with G are preparation functions, which indicate a specific task to the machine as it is: "Make a hole". "Mill a line". "Move there". 2/ The codes that start with M are various machine commands. They are usually used to turn something on or off, such as a.

CNC G Code Programming A CNC Mill Tutorial explaining G Codes YouTube

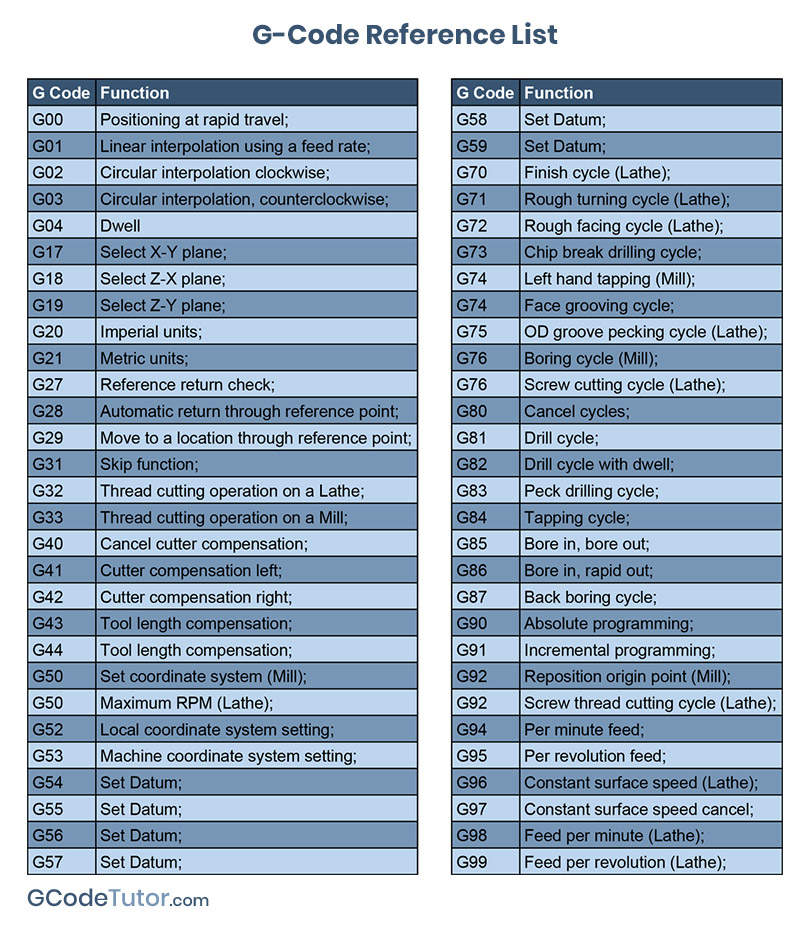

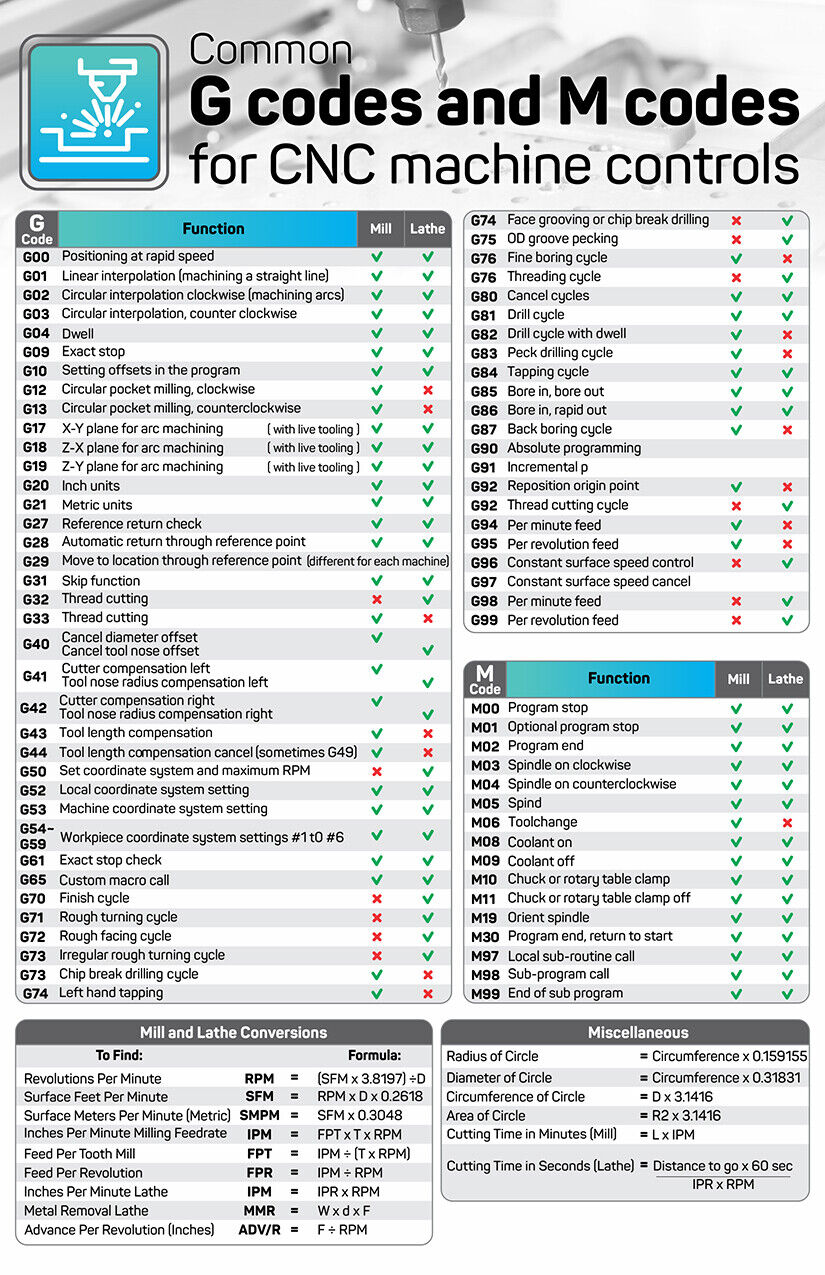

G-code is a series of preparatory commands used to control CNC machines. It can be programmed manually or using software programs. G-codes Used on CNC Mills The following is a list of G-codes used to program CNC mills and machining centers. List of G-codes used on CNC mills M-codes Used on CNC Mills

CNC G & M Codes Explanation Turning & Milling CNC Programming Explained with example YouTube

To create I & J codes you need to know the start point, end point and radius of the arc. The end point becomes the X and Y. The delta X and Y location relative to the radius centre point X and Y becomes the I and J values. You can also add a depth of cut value for Z as part of the block. Note that the Arc is assumed to run anticlockwise when.

CNC G Codes Learn how to program CNC machines with GCode

This video explains programming in G2/G3 mode with I and J for Haas mills, TSTC-Waco's Precision Machining Technology

Industrial Training and the Best PLC Training for Maintenance Cnc programming, Cnc, Diy cnc

How to mill a full circle, no problem below is the cnc program example G-code which shows how to program a full circle on a cnc milling machine. Often cnc… HAAS CNC Milling Machine Circular Interpolation Explanation with Example

Cnc Programming

How to Calculate I J K in CNC Programming (G Code) October 30, 2023 Leo Watts CNC Guides, Guides, Software, Software Guides Key Takeaways I J K method: Use the relative coordinates of the circle's center from the starting point to specify the circle. For example, G02 X8 Y0 I3 J4 K0. R method: Use the radius of the circle to specify the circle.

Cnc Programming

There are a few dozen CNC programs, some have specific requirements, but in general, the line blocks are basically the same. I hope this will simplify the I,.

CNC Milling G+M Code List Metalworking Industrial Equipment

G-Code for CNC Programming (2022 Update) Marti Deans May 24, 2018 8 min read This post is also available in: Italiano (Italian) Deutsch (German) You know what they say about fundamentals: learn them first, and you'll remember them forever. The same holds true for CNC machine programming.

Common G and M Codes For CNC Machines PDF

What Are G-Codes in CNC Programming? G code (also RS-274D) is the most popular CNC programming language. Most G code commands are in alphanumeric format and start with G which stands for geometry. They are responsible for the movements of CNC machines, telling the machine where to start, how to move, and when to stop when fabricating a part.

MCodes are often on each CNC machine as the machine manufacture add thier own custom

The G-codes that are marked with an * are used in conjunction with coordinates. G codes G00 = rapid movement G01 = move in a straight line at the specified feedrate* G02 = clockwise arc or circle movement* G03 = counter clockwise arc or circle movement* G04 = Dwell G17 = X Y plane selection G18 = X Z plane selection G19 = Y Z plane selection

Figure 7 from DESIGN AND IMPLEMENTATION OF FPGA BASED G CODE COMPATIBLE CNC LATHE CONTROLLER

Mozaik CNC Version has everything a cabinet workshop needs to run its CNC Router. From design & cut lists to nesting & machine-ready G-Code it is a complete CNC Software

CNC CODES EXPLAINED 15 G&M CODES YOU MUST KNOW CNC Programming Tutorials VMC 2 YouTube

G-code is the simple programming language for CNC machines. It consists of lines of code that are organized in blocks. Each block controls one CNC machining operation, such as a cutting operation with a specific tool. Each line in a block is labeled with the letter N and a number. These line numbers are generally only even numbers (N2, N4, N6.

Common GCodes & MCodes for CNC Machines Chart 5.5"x8.5" eBay

T o control CNC machines we use commands called CNC G Codes. Although Different manufactures of the machine tool may adopt their own use for certain G Codes there is a core group that is common on every machine tool. These standards are used on CNC Lathes, Milling machines, routers and more recently by 3D printers (in a very basic form).

Gcode数控机床编程教程【CNC】 BimAnt

G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using G code can realize fast positioning, anti circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump machining.